Capitalizing on Tremendous Market Potential.

Automated fill plant captures a rapidly growing market.

B&J Welding Supply’s fifth and newest location in Midland, Texas exceeds all customer expectations as it takes on the gas market deep within the Permain Basin, the most prolific oil-producing region in the United States.

Technology for Today—and Tomorrow

B&J Welding’s new facility features a fully automated palletized fill island with complete pump control and regenerative variable-frequency drives. It also houses automatic liquid-fill manifolds, medical E-oxygen fill manifolds, helium-filling equipment with booster pump, and a specialty-gas lab

– all designed and built by Weldcoa. And after just a few months of operating the new facility, the reaction from the market has been unprecedented.

“The market in this area is industrial-gas intensive,” said Steve Hodges, B&J project manager and part owner. “As the region’s oil and gas business has exploded, so has the need for state-of-the-art welding technology, including higher-quality welding gases. Our customer base has grown to include several high-end weld shops, and they’ve all been very impressed with what we’re able to produce here, thanks to our new Weldcoa systems.”

The four-head fill island, two for inerts and two for oxygen, are each capable of simultaneously filling 16 cylinders. While that’s more capacity than the firm needs today, Hodges credits the Weldcoa team helping him look ahead to what it likely will need to handle future growth.

“The first thing Weldcoa did when we brought them onboard to spearhead the project was to concentrate on learning our business,” Hodges said. “Their project managers spent time understanding how the fill island and other equipment would fit into our business plan. Much more than just selling a system, Weldcoa worked to ensure that our team—and theirs—understood not only what we needed today, but what we would need tomorrow. So, while at first look we thought one mixed-gas fill head would suffice, Weldcoa convinced us to add the second mixed-gas head. Add in the other systems—liquid-fill stations for inerts, oxygen and CO2, and medical and E-cylinder racks, plus the spec-gas lab—and we’re set for at least the next 3 to 5 years of projected growth.”

Automation Delivers on Demand

Keeping pace with demand for welding gases is not the only challenge B&J faces; local weld shops also look for higher quality in terms of gas-mix

accuracy and repeat-ability. In planning the new fill plant, Hodges and his team knew that the company couldn’t rely solely on production from its manually operated Lubbock fill plant. “That plant was very dependent on the expertise of the operator,” said Hodges, “and it takes great attention to detail to achieve the higher levels of purity required from customers in the medical and other industries.” So, Hodges and his team set out to benchmark an automated fill plant, eventually visiting a recent Weldcoa customer that is fully automated. “Seeing how the distributor leveraged the automation to drive throughput and optimize consistency and purity helped convince us to automate our new plant. Automation takes some of the need for operator expertise out of the picture, thanks to the many features with the island’s control terminals,” noted Hodges.

“The growth of our customer base, and their incredibly positive reaction to our new systems, level of quality and responsiveness, tells me our investment was the right decision at the right time.”

Steve Hodges, Project Manager, B&J Welding Supply

Audible commands emanating from the island control stations guide operator actions while giving them the flexibility to move around the fill plant

and perform other jobs, rather than having to stand in front of the control screen and babysit the system. “In this area of Texas, where technical expertise has become a hot and relatively rare commodity,” said Hodges, “we felt that the automation was a necessary investment.”

Hodges also sings the praises of having variable-speed drives (VSDs) controlling pump speed. “That’s a big deal,” he added, “especially in the heat of the summer. On the hottest of days, without VSDs we’d only be able to pump early in the morning before it gets too hot. That can really inhibit production.” With VSDs, when the temperature rises B&J can slow the pumps and keep them safely within their operating-temperature range. “While we might be pumping a little more slowly,” said Hodges, “at least we’re able to keep production going throughout the day.”

Transition Without Disruption

The new Weldcoa systems were installed in approximately 7000 sq. ft. of the Midland plant’s 20,000-sq.-ft. footprint. The location also includes retail and office space, a small warehouse,and the Weldcoa-equipped spec-gas lab. “Again, the preparation and planning by the Weldcoa team paid huge dividends,” he said, recalling the synchronization of the new building construction and fill-plant installation. “Weldcoa gave us and our construction team every detail we needed to ensure we had no installation surprises.”

Weldcoa trained three B&J employees to run the island, including one of their technicians from the Lubbock plant. “The Weldcoa team didn’t leave here until they were sure we were comfortable with the equipment,” Hodges added. “And even now, long after the training has been completed, Weldcoa continues to respond to our phone calls and e-mail requests for support.”

Information Serves Customers and Sales

“We have also provided training to our sales team. They’ve all spent time watching the automated fill island run, talking to the operators about what’s happening and why the automation helps improve productivity and quality. This knowledge lets them communicate better with their customers and prospects—this is critical, I believe, to ensuring we know how to sell our new capabilities,” noted Hodges.

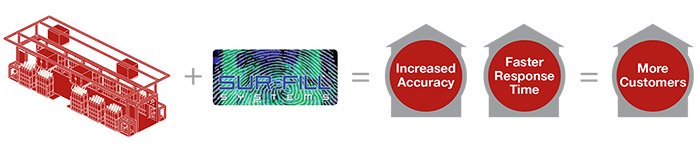

In addition to the other benefits from automation, the Sur-Fill software delivers reporting. “The software provides the gas-quality documentation our customers have begun to request on a regular basis. They in turn often are required to provide that same documentation to their customers. Sur-Fill, therefore, strengthens our link in the supply chain,” concluded Hodges.