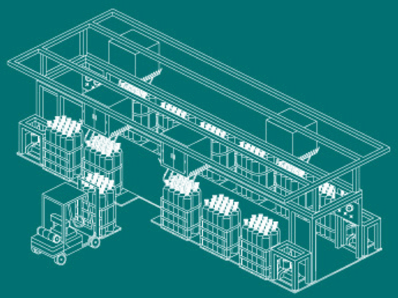

Weldcoa is the recognized leader in independent manufacturing of Fill Systems. The Weldcoa Modular Filling Equipment is designed for rapid, minimal cost, installation into new or existing facilities. Our process has been developed over the last 50 years and continues to be refined. Building the equipment in the controlled environment of the Weldcoa plant prior to delivery reduces labor, engineering and overall planning costs dramatically.

The Benefits of Using a Weldcoa Pallet Fill System

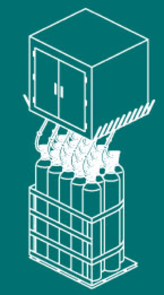

On our Pallet Fill Systems, cylinders on a pallet are placed into an organized bay area. Depending on the style that you choose, those cylinders can be sorted, inspected, and filled from that station in an organized, safe, efficient fashion. We offer both manual and automated packages with this fill system design. The operator stations can be a manual control panel style, an automated touchscreen or a combination of both. In regards to the Fill Head, operation is simple; the leads pull down and when released, recoil back into the Fill Head.

Several key features are integrated into the fill head design include:

The Benefits of Automating Your Fill Process

Our Sur-Fill Automation is a highly efficient, cost effective, safe alternative to conventional manual filling methods. Weldcoa has several levels of automation to choose from allowing the operator to be freed up to do more operations during a fill cycle. Eliminating time loss during wait, cycle transitions and monitoring times. Due to the laws of physics, you simply cannot fill faster safely but with Weldcoa Sur-Fill Automation you can….

How it All Works

The Sur-Fill Mix Gas Cylinder Filling System allows the operator to fill Straight Gas, Industrial Mixes, Medical Mixes and Specialty Mixes. The operator commands and monitors the filling system through the use of a graphical operator terminal. The terminal is a touch screen device with virtual “buttons”. The terminal will respond to bare and gloved hands.

Gases are filled automatically using pre-defined formulas. A reference cylinder on a weigh scale is used by the control system to monitor the addition of gas components. The combination of controlling pump speed and the use of a throttling valve permit the system to achieve accurate results. The operator selects formulas, filling options, enters production tracking data and can monitor the progress of the fill through the use of a touch screen operator interface.

Production data may be automatically recorded by a remote computer. The operator must provide information about the cylinders being filled in order for the data to be meaningful. The Production Data screen is used to enter information about the batch of cylinders to be filled. This information is communicated to a remote computer for generating production reports. When an operator touches one of the fields, a keypad drop down box appears to permit data entry.

CHECK OUT OUR CASE STUDIES AND SEE HOW THE PALLET FILL SYSTEM WORKS FOR OTHERS IN OUR INDUSTRY.

Taken at Encore Welding's Fill Facility in Signal Hill, CA

Taken at Holston's Fill Facility in Knoxville, TN

View ProductTaken at Praxair's Fill Facility in Mexico City

Taken at Praxair's Fill Facility in Mexcio City

Taken at Nexair's Fill Facility in Memphis, TN

Taken at B&J Welding Supply's Fill Facility in Midland, TX

View ProductTaken at B&J Welding Supply's Fill Facility in Midland, TX

View ProductTaken at Norco's Fill Facility in Boise, ID

Taken at Cee Kay Supply's facility in St. Louis, MO

View Product

Ed Conrad, Fill Plant Manager, General Air Service

Ed Conrad, Fill Plant Manager, General Air Service

Kevin Kimker; Director of Gas Operations at Cee Kay

Robert Parsons, Holston Gases, Operations Manager

Located in Aurora, IL, Weldcoa is an innovative US manufacturer of products that store, transport, fill, supply and/or analyze compressed gas, cryogenic liquids, high pressure liquids and supercritical fluid. Our cross-disciplinary team of experts bring an in-depth knowledge of gases to every project. You can count on their passion and commitment to make your project a success.

Call 630-806-2000 or email us at solutions@weldcoa.com today to get started.